TPMS

Concept Garage Equipment can supply a range of Tyre Pressure Monitoring System (TPMS) sensors, diagnostic tools and TPMS valves direct to all garages and workshops or MOT test stations. To discuss your TPMS requirements call us today on 0113 469 0572 or head to our contact us page and one of our TPMS diagnostic experts will call you right back.

We won’t be beaten on customer service, and more often than not we also won’t be beaten on price!

Showing all 15 results

-

TPMS Valves Box Of 20 Replacement Clamp-In Valves for VDO TG1C

£68.32 +VAT Add to basket -

TPMS Box Of 10 Replacement Clamp-In Valves for Schrader Gen 4 (72-20-448)

£68.32 +VAT Add to basket -

TPMS Box of 20 Replacement Clamp-in Valve VDO TG1B (72-20-453)

£68.32 +VAT Add to basket -

TPMS Box Of 40 Service Kits for Schrader Gen 2/3 (72-20-507)

£68.49 +VAT Add to basket -

TPMS Box Of 40 Service Kits for VDO TG1B (72-20-505)

£68.49 +VAT Add to basket -

TPMS Box Of 40 Service Kits for VDO TG1B (72-20-511)

£68.49 +VAT Add to basket -

TPMS Box Of 40 Service Kits for VDO TG1B (72-20-506)

£68.49 +VAT Add to basket -

TPMS Box Of 20 Replacement Clamp-In Gen 2 Valves for Huf – 43mm (72-20-454)

£70.89 +VAT Add to basket -

TPMS Box Of 30 Replacement Snap-In High Speed Valves for Schrader Snap-In Sensor (72-20-449)

£88.55 +VAT Add to basket -

TPMS Sensor Hamaton EU-Pro Hybrid 3.5 3200 Clamp-In Valves Chrome (pack of 4 or 10)

£117.31 – £293.28 +VAT Select options -

TPMS Sensor Hamaton EU-Pro Hybrid 3.5 3200 Snap-In Valves Black Rubber (pack of 4 or 10)

£117.31 – £293.28 +VAT Select options -

TPMS Sensor Autel Programmable MX-Sensor valves (pack of 4 or 10)

£120.63 – £297.43 +VAT Select options -

TPMS Box Of 100 Replacement Snap-In High Speed Valves for Schrader Snap-In Sensor (72-20-449)

£295.15 +VAT Add to basket -

TPMS Relearn Tool Autel TS508K Maxi

£410.80 +VAT Add to basket -

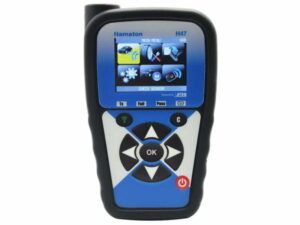

TPMS Relearn Tool Hamaton H47 with OBDII Module and 5 years FREE updates

£540.79 +VAT Add to basket

What is a TPMS?

Tyre Pressure Monitoring System or TPMS is a valuable safety feature and has been required on all passenger cars in the United Kingdom since November 2014, and fitted to all vehicles in the United States since 2008.

A Tyre Pressure Monitoring System (TPMS) is an electronic system that monitors tyre air pressure and alerts the driver or vehicle user when the pressure is incorrect in the vehicle tyres. Parts of the TPMS system are usually integrated into the car’s electronic control system.

The main purpose of a TPMS is to warn the driver when tyre pressure is too low, usually, this indicates that the pressure dropped below a minimum tolerance level or by a % deviation from the manufacturer's recommended pressure. Maintaining the correct tyre pressure helps to prevent uneven tyre wear, and potential tyre blowouts but also helps to improve fuel efficiency and both ride and steering comfort.

What are the Types of TPMS Systems?

There are 2 different types of TPMS Systems, Direct TPMS and Indirect TPMS.

Indirect TPMS Systems: Indirect TPMS systems do not have TPMS Sensors inside the tyre or wheel rim. Instead, the Anti-lock Brake System (ABS) wheel speed sensors are used on the vehicle to calculate the tyre pressure across the 4 tyres, meaning there is no need to fit individual TPMS tyre valves, but also means that the readings tend to be less accurate as they are not tyre-specific readings, but rather an assessment looking for inconsistencies across the 4 wheels of the vehicle.

Direct TPMS Systems: As per the products sold by Concept Garage Equipment, the direct TPMS sensors tend to be more popular, and more accurate, and are fitted as part of the tyre valve. The vehicle computer then reads this data for each sensor.

Please note: all other information on this website, FAQ and product data that we sell relates only to Direct TPMS Systems.

How does TPMS work?

A Tyre Pressure Monitoring System (TPMS) typically uses sensors mounted on each wheel that send data to a central controller.

The TPMS sensor usually forms part of the tyre valve (that is used to inflate the tyre), and the end of the valve that is within the wheel itself tends to have the TPMS monitor, including the embedded battery within.

When the TPMS sensor is initially added or replaced within the wheel, it needs to be taught (often referred to as the relearn procedure) to know which vehicle it has been added to, to enable it to talk correctly to the vehicle TPMS controller system and to identify the pressure of the tyres correctly to which it has been fitted.

The TPMS controller, which is usually part of the vehicle computer then uses the data that is sent from the TPMS valve to determine whether the tyres are properly inflated or not.

If the tyre pressure falls outside of the recommended tolerance, as set by the manufacturer, then the driver or vehicle user will be alerted, usually by a warning light on the dashboard and potentially an audible alarm within the vehicle also. The warning light will usually stay lit when the ignition is on, until the tyre inflation has been corrected, and often the vehicle has to be driven for a short while for the re-learn procedure to detect the pressure has been adjusted also.

Please note: all information on this website, FAQ and product data that we sell relates only to Direct TPMS Systems.

Where are TPMS sensors located?

The TPMS sensors are usually embedded within the wheels and take the form of the inside or embedded end of the valve that is used to inflate the tyre.

The end of the valve that is within the wheel itself has the TPMS monitor, including the embedded battery within.

Please note: all information on this website, FAQ and product data that we sell relates only to Direct TPMS Systems.

When to replace TPMS sensors?

A sensor valve can last between 5 and 10 years or up to 100,000 miles and is generally determined by the life expectancy of the lithium-ion batteries inside the TPMS Valve itself, although this can vary depending on vehicle use, tyre damage or replacement, since the valve can be damaged whilst tyres are being changed.

Please note: all information on this website, FAQ and product data that we sell relates only to Direct TPMS Systems.