If you own a garage in the UK and you don’t already offer wheel alignment, not only could you be offering an extra service to your customers, but you could be missing out on an excellent revenue stream for your business.

Wheel aligners come in several different flavours, all of which will add value to your business, but let’s explore more about wheel alignment, and help you decide if it’s something you should be offering your customers.

What is a Wheel Aligner?

A wheel aligner is a mechanical device or machine used to align the wheels of a vehicle.

Some wheel aligners are simple lasers that are bolted to a vehicle wheel and shine a straight laser line to the other wheel on that side of the vehicle to assess whether the wheels are in line.

Other more advanced wheel aligners, often called CCD aligners, use a combination of lasers, cameras and computer-controlled software to make accurate measurements of the wheel positions both against each other and to the manufacturer’s recommendations, usually stored in a database as part of the wheel aligner software program.

What does a Wheel Aligner do?

Wheel alignment sometimes referred to as wheel tracking, is part of the standard car and vehicle maintenance that consists of adjusting the angles of wheels to the car manufacturer’s specifications.

The purpose of making these adjustments is to reduce tyre wear and to ensure that the vehicle travels in a straight line, keeping the steering wheel straight without pulling to one side or the other.

This is important for maintaining the vehicle and keeping it running smoothly. Wheel alignment can help improve fuel economy, as well as prolong the life of the vehicle tyres, as incorrect wheel alignment or tracking can cause excessive tyre wear on one side.

Motorsport and off-road vehicles may require alignment angles to be adjusted well beyond the normal manufacturer recommendations, and you would not use a standard vehicle wheel aligner for these exceptions.

Types of Wheel Aligner

There are several types of wheel alignment machines available in the market. Here are some of the most common ones:

- Laser wheel alignment machine: This type of machine uses fixed heads that attach to the wheels of a car and use laser beams to measure the angles and positions of the wheels. It is a basic form of wheel alignment and is generally considered less accurate than computer-controlled CCD or 3D alignment systems but can be more robust and reliable.

- CCD wheel alignment machine: This type of machine is computer-controlled and uses cameras either connected to the main alignment machine or on the heads attached to the wheels of the car to measure the angles and positions of the wheels. The alignment data is read from a database by the on-built computer to ensure accuracy and it can detect small misalignments from the manufacturer’s recommendations.

- 3D wheel alignment machine: This type of machine uses three-dimensional imaging technology to measure the angles and positions of the wheels. Again, the vehicle data is supplied from an up-to-date database of vehicle data supplied by the machine. It is fast and very accurate and can detect even the smallest misalignments.

- Portable wheel alignment machine: This type of wheel alignment machine is designed for mobile mechanics or small shops that don’t have a dedicated alignment bay. It is lightweight and easy to move around, but it may not be as accurate as the other types.

2 Wheel Alignment vs 4-wheel alignment

Every form of alignment has its advantages and disadvantages however it’s generally understood that 2-wheel CCD alignment gives better results than basic laser wheel alignment and 4-wheel alignment or 3D wheel alignment goes one stage further in terms of alignment accuracy.

You must decide on the aligner that suits your budget of course, but if you can afford to go for a 4-wheel alignment machine, then you should.

How is Wheel Alignment done?

Wheel alignment is the adjustment of a vehicle’s suspension components. The most common adjustments are to the caster, camber and toe angles. However, other adjustments can be made to the vehicle’s suspension. The purpose of these adjustments is to reduce tyre wear, increase safety whilst driving by ensuring the maximum rubber is in contact with the road surface and ensure that the vehicle travels in a straight line without excess force pulling to one side or another.

It is generally recommended for vehicles to get a wheel alignment done at least once a year, as well as any time the wheels or tyres are changed on the vehicle, or after any damage repair is done to it.

How long does a Wheel Alignment take to do?

A wheel alignment will take roughly an hour to perform, for either a two-wheel-drive or four-wheel-drive vehicle, some variations will apply depending on the particular wheel alignment system being used of course.

The overall job may end up taking much longer if issues with the wheels, tyres, suspension system, or other components need to be inspected or replaced.

Which Wheel Alignment machine is best?

The correct wheel alignment machine for you depends on several factors:

- What class of vehicles do you intend to align the wheels on?

- How accurate you would like the alignment of the wheels to be?

- What space do you have for the aligner?

- What budget do you have to spend on a wheel alignment machine?

- How many wheel alignments will you be doing per day?

If you wish to discuss your wheel aligner requirements, we can help you decide on the best wheel aligner for your garage or MOT Bay, please contact us on 0113 469 0572.

How profitable is wheel alignment to a garage?

In a word, very! Following your initial investment into a wheel alignment machine, the running costs are extremely low, with occasional database updates (some alignment machines may have live data with pay-as-you-go costs) and calibrations, hence once the machine has paid for itself, the vast majority of the income received thereafter is pure profit.

Before even getting started on a wheel alignment, you may find that tyres, weights, suspension, steering or braking components are due for replacement or repair, hence these additional checks add an additional level of safety to the customer visit.

Hence, wheel alignment is considered one of the most valuable services a garage can offer to customers in terms of revenue and profit to the business.

As an example, even if you bought our most expensive 3D wheel aligner and performed 5 alignments per day, it would more than pay for itself in less than a month!

You can try out examples of this using our handy online Wheel Alignment Profit Calculator.

Let us help you get into Wheel Alignment

When considering investing in wheel alignment equipment for your garage or MOT Bay, upgrading your garage, or setting up a new MOT business there is a lot to think about.

Concept Garage Equipment has years of experience in helping hundreds of garage businesses go through this transition, and we know all the pitfalls along the way. We are happy to advise you to ensure your journey is smooth into the world of wheel alignment. Still, if you want an extra helping hand choosing a wheel aligner, getting the required training, and helping to get it to earn revenue for your business as quickly as possible we are on hand so that you don’t need to go through this process alone.

For a no-obligation conversation about your wheel aligner purchase, usage or calibration or for a quotation contact us today at 0113 469 0572.

Glossary of Wheel Alignment terms

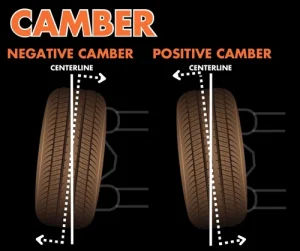

Camber: the inward and outward angle of the tyres compared to a vertical line when viewed from the front or rear of the vehicle, hence the top or the bottom of the tyre will be out of alignment, often caused by worn bearings, ball joints or damaged suspension components, also sometimes seen on cars where spacers are fitted incorrectly.

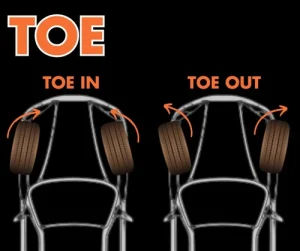

Toe Angle: Looking at your tyres from above (or below) if they are not completely in line with each other then we would say the toe is out of alignment. If the front edge of each tyre is relatively closer than the rear edges then we say they toe in, the opposite would mean they toe out. Both situations will result in uneven tyre wear, especially along the edges of the tyres.

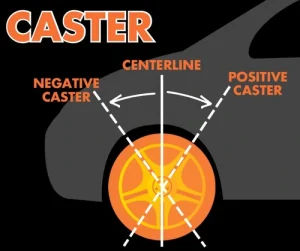

Caster: Looking at the wheel from the side of the car, the wheel should sit central to the suspension components and centrally within the wheel arch. If the wheel is not completely upright from this angle we say that it has either a negative caster (it’s leaning backwards) or a positive caster (leaning forwards). Steering can be adversely affected if this is not set correctly.

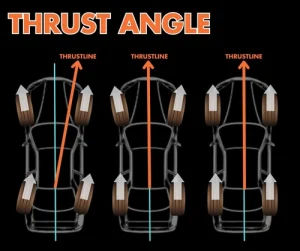

Thrust angle: This is used to determine if the rear axle is properly aligned with the front wheel axle of the vehicle, as this alignment should be the equivalent of a straight line drawn from the centre of the rear axle to the centre of the front, and any deviation from this would cause curved or meandering of the vehicle under acceleration as the forward thrust would happen at a less than straight angle, and the driver would constantly be correcting the steering angle whilst driving.

Learn more

If you have any questions about wheel alignment or anything in this article please give our friendly sales team a call on 0113 469 0572.